wire edm machine is an electro process

The FW of 015mm wire electrode is adjusted to 7. This process allows the wire to cut through metal by the use of heat from electrical sparks.

Wire Cut Electro Discharge Machining Process Working Animation Video Explained With Setup Diagram Youtube

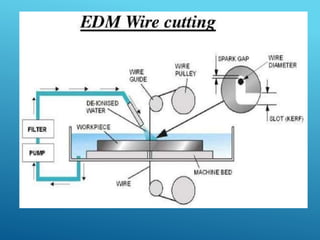

The wire and the workpiece are submerged in a dielectric fluid and sparking takes place in the spark gap between the wire and the workpiece surface.

. Usually the work piece and wire are submerged in deionized water. A non-conventional process though hardly a new one wire EDM works on parts resistant to conventional. Machine to optimize the material removal rate MRR which Experimental results have shown that the conventional is directly increases with increase in pulse on time TON responses experienced in the traditional Wire-Cut EDM and peak current IP while it decreases with increase in process can be effectively improved by adopting the Grey pulse off time TOFF and the servo voltage.

Wire Electrical Discharge Machining or Wire EDM is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity allows the wire to cut through metal by the use of heat from electrical sparks while preventing rust. Your EDM process is recommended for machining die cavities with intricate and complicated shapes in materials listed above and the cavities can be blind or through. He noticed that the sparks had eroded some of the electrode material.

Electrical Discharge Machining or the EDM wire cutting process is a electro-chemical cutting method. Wire EDM or Wire cut Machine. What is Wire EDM.

Basically you have two types of EDM machines. If you change to 015mm or 01mm electrode wire you must reduce this tension value otherwise it will be in the process of wire alignment. Almost 200 years later in 1940s Soviet Russia two scientists.

Only a slight bit wider than the wire electrode itself. Types of EDM Machines. Wire EDM is commonly used on hard metals which are often difficult to machine.

Both of these should be electrically conductive. The dielectric fluid acts as a insulator between the electrodes and. The theory on which Electrical Discharge Machining EDM is based is centuries old.

The arbor is the drive shaft of the machine which rotates at high speeds in order to force metal into the cutting area. Its quite like a cheese cutter. Wire EDM which came into commercial use in the 1960s uses a wire stretched taut as the electrode.

Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is obtained by using electrical discharges sparks. Wire EDM machining is an electro thermal process which utilizes a thin metal wire in a bath of with de-ionized water which is used to conduct electricity. Wire Cut EDM makes more complex and critical cuts compared to the conventional Electric Discharge Machine.

An edm machine contains three main components. A potential difference is created between the electrode tool and workpiece. The Arc and Arc Connection Error Alarm.

Wire EDM uses a straight tensioned wire as the electrode which is slowly drawn through the workpiece to cut a ribbon-like path. This method is popular because of the fact that EDM can machine any materials irrespective of its hardness. An EDM drill uses a tubular electrode to burn a hole through conductive material.

Electrical discharge machining EDM is a popular nonconventional machining approach that is often used on hard materials. Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes separated by a dielectric liquid. It offers the finest kerf process available for cutting metals.

Wire breakage will occur. The nature of the Wire EDM process means that you can achieve shapes and structures that are next to impossible with other CNC methods and can give you incredible results. Both 4-axis and 5-axis wire EDMs machines can be purchased from the market.

An EDM Wire-cut machine uses a continuous thin electrically conductive wire as the electrode to cut profiles on the workpiece and this process is called wire cutting. Wire filters and other consumables used on wire EDM machines. The cut width kerf is very narrow.

An arbor the electrode holder and the dielectric fluid. Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. Wire EDM is a type of CNC machining technology capable of unique results.

Electrical discharge machines work on the principle of material removal using a series of electric Spark discharges occurring between the electrode tool and the workpiece. Modern engineering materials that are deployed in extreme conditions are often shaped or manufactured by. An EDM machine is the piece of equipment used to carry out this manufacturing process.

What Is EDM Machining EDM is a machining process that uses electrical currents to cut metal. The FW of 01mm wire electrode is adjusted to 3. Wire Cut EDM Electrical Discharge Machining Image credit.

Sinker EDM or Ram EDM. The principle behind EDM was first observed in 1770 by Joseph Priestley who was experimenting with electrical discharges. Wire EDM Machining is an electro thermal production process where a thin single-strand metal wire in conjunction with de-ionized water used to conduct electricity allows the wire to cut through metal by the use of heat from electrical sparks.

Wire Edm Find Suppliers Processes Material

Wire Cut Edm Process 2 Download Scientific Diagram

Line Diagram Of Wire Cut Edm Process Download Scientific Diagram

Wire Edm Find Suppliers Processes Material

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Wire Edm Machining Sprutcam 14 All Lang User Manual

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

What Is Wire Edm Electrical Discharge Machining Xact

Wire Electric Discharge Machining Wire Edm Youtube

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

What Is Wire Edm Electrical Discharge Machining Xact

Block Diagram Of Wire Edm Machine Source Technological Manual Of Download Scientific Diagram

Principle Of Wire Cut Edm 1 Download Scientific Diagram

Wire Edm Introduction As We Build Our Knowledge Database We By Factorem Medium

Study Of Process Parameter Of Wire Electric Discharge Machining The Review Semantic Scholar